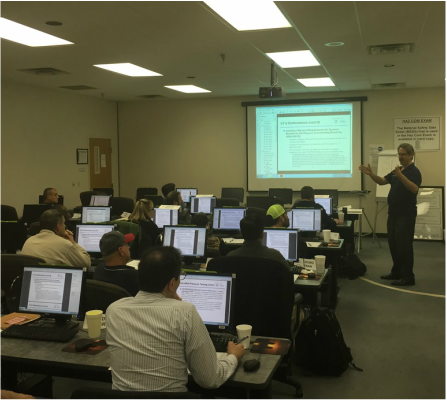

TRAININGDuring the 3 day training session you will learn about a wide spectrum of topics related to ASME Section XI and ISI. If you're wondering what is covered in our training, see below for a list of objectives IE strives to attain during each session.

If you are interested in attending an ASME Section XI Training, contact us to join the next scheduled training course. If multiple employees are interested in ISI, we can set up a training at your own office. |

Feedback from Attendees of the IE Section XI Training

"Excellent lesson plan, presentation, and class participation. Instructors very knowledgeable in ASME Code and Regulatory Requirements."

"Classroom instructors provided lots of relevant industry experience and insight that very much enhanced the presentation. Downloading the presentation and supporting material onto a memory stick was a great use when reviewing the material off-hours. I am new to the Program Engineering area and feel much better prepared for my new responsibilities."

"Great presentation with great support materials. Knowledge of instructors was top-notch."

"Presentation, materials, and instructors were excellent. There was a lot of material to get through and I will be keeping the information provided in class as a future reference."

"Great training - should be an introductory course for all Engineering personnel. Pace was great - not too slow or fast."

"Instructor knowledge was impressive. Great training and intro to ASME XI."

"Excellent lesson plan, presentation, and class participation. Instructors very knowledgeable in ASME Code and Regulatory Requirements."

"Classroom instructors provided lots of relevant industry experience and insight that very much enhanced the presentation. Downloading the presentation and supporting material onto a memory stick was a great use when reviewing the material off-hours. I am new to the Program Engineering area and feel much better prepared for my new responsibilities."

"Great presentation with great support materials. Knowledge of instructors was top-notch."

"Presentation, materials, and instructors were excellent. There was a lot of material to get through and I will be keeping the information provided in class as a future reference."

"Great training - should be an introductory course for all Engineering personnel. Pace was great - not too slow or fast."

"Instructor knowledge was impressive. Great training and intro to ASME XI."

ASME Section XI and Inservice Inspection (ISI) Training Objectives:

SECTION I: INTRODUCTION TO INSERVICE INSPECTION

A) Define inservice inspection

B) Describe why inservice inspections are required

C) Review the applicable documents

D) Describe the available alternative requirements

E) Review the ASME code process

F) Review jurisdictional criteria

G) Describe classification boundaries and how they are determined

H) Review the impact of plant activities on ISI

SECTION II: ASME SECTION XI

A) Describe the organization of the ASME Section XI Code

B) Provide a further breakdown of ASME Section XI Subsections

SECTION III: EXAMINATIONS AND INSPECTIONS

A) Describe the applicable nondestructive examination (NDE) methods

B) Describe the qualification requirements for NDE personnel

C) Describe Inspection Programs

D) Discuss Inspection Plans

E) Describe inspection intervals

F) Discuss weld reference systems

G) Review the differences between preservice inspections (PSI) and inservice Inspections (ISI)

H) Identify which components are exempt from inservice inspections

I) Describe examination requirements for specific components

J) Identify examination surfaces and volumes that require inspection

K) Discuss successive examination requirements

L) Discuss additional examination requirements

M) Identify augmented examination programs and their requirements

N) Review potential code cases that provide alternative criteria for examination requirements

SECTION IV: RISK-INFORMED INSERVICE INSPECTION

A) Provide a background on risk-informed inservice inspection (RI-ISI) programs and how they interface with standard

inservice inspection programs

B) Define risk

C) Describe the steps involved in a standard risk-informed methodology application

D) Discuss the two risk-informed inservice inspection methodologies and their corresponding Code Cases

E) Discuss the reduction in cost and radiation exposure associated with a risk-informed inservice application

F) Describe program update requirements

G) Describe other ongoing risk-informed developments

SECTION V: EXAMINATION EVALUATIONS

A) Describe how to characterize a flaw

B) Define the types of flaws

C) Discuss acceptance criteria

D) Describe supplemental examinations

E) Review Code acceptance standards for specific components

F) Discuss analytical evaluations

SECTION VI: REPAIRS AND REPLACEMENTS

A) Discuss the combination of repair activities (IWX-4000) with replacement activities (IWX-7000) in the 1991

Addenda of ASME Section XI

B) Provide a definition of repair/replacement activities

C) Distinguish code repairs and replacements from non-code repairs, replacements and modifications

D) Discuss use of Non-Mandatory Appendix J

E) Review applicability and exemption criteria

F) Discuss Repair/Replacement Programs

G) Review the requirements for Repair/Replacement Plans

H) Review code reconciliation requirements

I) Discuss the requirements for welding, brazing, metal removal and installation

J) Describe special repair processes (alternative welding methods) such as temper bead welding and underwater welding

K) Discuss heat exchanger tube repair/replacement requirements

L) Discuss what is meant by the term “rerating”

M) Discuss 10CFR50.55a concerns for the use of mitigation of flaws by encapsulation

N) Describe examination and testing requirements for repair/replacement activities

O) Review potential code cases that provide alternative criteria for repair/replacement requirements

SECTION VII: PRESSURE TESTING

A) Discuss pressure testing that is required after repairs and replacements

B) Discuss periodic pressure testing requirements

C) Review system leakage tests/ system pressure tests requirements

D) Discuss hydrostatic tests and available alternatives

E) Review 10CFR50, Appendix J testing for Class MC components

F) Discuss testing boundaries

G) Review test temperature and pressure requirements

H) Discuss hold times

I) Review insulation removal requirements for systems borated for the purpose of controlling reactivity

J) Review the testing requirements for buried piping

K) Discuss corrective actions that must be taken

L) Review potential code cases that provide alternative criteria for pressure testing requirements

M) Discuss potential augmented pressure testing criteria

SECTION VIII: DOCUMENTATION REQUIREMENTS AND DATA MANAGEMENT

A) Review the applicable requirements of the Code of Federal Regulations

B) Review the applicable requirements of ASME Section XI

C) Review the elements of a comprehensive ISI data management program

OPTIONAL SESSION IX: ISI PROGRAM DEVELOPMENT AND UPDATE

A) Review the aspects of an ISI Program update

B) Evaluate and close-out current ISI interval

C) Address 10CFR50.55a Limitations and Modifications

D) Discuss classification boundaries and associated drawings

E) Determine applicable Code Edition and Addenda

F) Perform comparison of Code Editions and Addenda between current and upcoming interval

G) Determine applicable Code Cases

H) Incorporate or update Risk-Informed ISI application

I) Prepare Relief Requests and Requests for Alternatives

J) Address augmented examination commitments

K) Review and update ISI isometric and component drawings

L) Review and update ISI database

M) Generate ISI Plan for submittal to NRC

N) Select and schedule items for examination

O) Generate and update necessary documentation

P) Update implementing and NDE procedures

Q) Update related programs (e.g., Repair/Replacement, Pressure Testing, Containment ISI, etc.)

R) Address NRC questions and comments

| ASME SECTION XI AND INSERVICE INSPECTION (ISI) TRAINING OBJECTIVES | |

| File Size: | 47 kb |

| File Type: | doc |